Panel Session: Immersive technologies for inspection, maintenance, and service

Joining the ranks of technologies such as artificial intelligence and machine learning; augmented reality is swiftly proving its worth in the manufacturing and plant operations space. At the same time Virtual Reality ushers in the next paradigm in enterprise training for safety and technical needs.

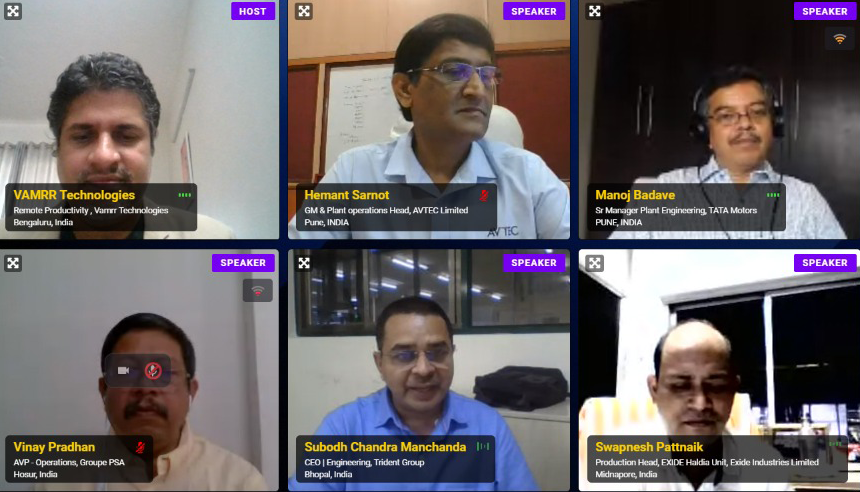

The panel on Immersive Technologies for Inspection, Maintenance and Service operations at the VAMRR REMOTE PRODUCTIVITY SUMMIT – PLANT OPERATIONS EDITION held on 10 Sep 2020, featured distinguished speakers with the experience, expertise and the vantage point. They shared insights into where immersive was adding value and how its potential was already being untapped with a lot more in store….

Featured Panelists:

- Hemant Sarnot | GM & Plant Operations Head, AVTEC Limited

- Manoj Badave | Senior Manager, Plant Engineering, TATA Motors

- Vinay Pradhan | Assistant Vice President, Operations, Groupe PSA

- Subodh Chandra Manchanda | CEO Engineering- Trident Group

- Swapnesh Pattnaik | Production Head, Exide Haldia Unit, Exide Industries Limited

Moderated by

Anand Gurnani | Founder, VAMRR Technologies

On Augmented Reality

Mr. Hemant Sarnot, GM & Plant operations head AVTEC Ltd., began the session by sharing that Augmented Reality is one technology that has taken a big leap in the last couple of years.

“He shared his experience of using AR for inspection and maintenance activities in manufacturing setup. Live AR lenses can guide you through complex assemblies, contextually displaying relevant information that is needed for the inspection. You can also do visual inspection, compare physical parts with 3D augmented parts”

Mr Sarnot highlighted that his company was proactive in Industry4.0 initiatives and as part of that had procured google lens early on. “We used it for inspection and report generation as well. With the live screen, you can check and tick through an inspection check list in real time and eventually a report is generated. Of course, it needs to be integrated with your systems before you can use it.”

“Our R&D engineer sitting in Switzerland was able to see the material as if he was holding it in his hand, thanks to AR. That was a great use case” he said.

Subodh Chandra Manchanda, | CEO Engineering- Trident Group, shared that “We have done a 3 months pilot project with Mobile Phone based AR and we have recently also procured smart glasses. Our initial use case was for remote assistance, maintenance, and engineering purposes, however during the pandemic we realized more use cases of such technology”.

Mr. Manchanda profoundly claimed that they would be able to provide virtual tours of their manufacturing facilities to their US based clients through Augmented & Virtual Reality. “Sitting at home on a Sunday we as well as clients can inspect the quality of the sheets and towels.”

He attributed the technological savviness of his Chairman R/RG to the proactive and technology-oriented management.

Mr. Vinay Pradhan, AVP Operations Groupe PSA resonated with his fellow panelitsts articulating “Distance Means nothing and one can work with colleagues thousands of miles away in real time”.

On Integration of Artificial Intelligence, Computer Vision & Augmented Reality

Mr Sarnot who had earlier shared about his experience with Google Glass, next spoke about the way emerging technologies were integrating to create value.

“Interface between AI, Computer Vision & AR is a big thing for manufacturing. Another important development is mixed reality, though it is in a nascent stage” he said.

He shared an example of a self-inspecting component “There is an environment with 3 cameras at different locations around the machine. The camera feed uploads itself and compares the machine with pre-loaded 3-dimensional models and it is able to self-inspect. It used Computer vision.” He pointed out that automotive companies were especially quick in adopting the latest technologies.

On why Remote Assist with AR is much better than only a video call?

“We were challenged by people, Why AR? Why not a video call?” shared Mr Manchanda “With AR you are able to clearly point out the right spot and the right parts that have the potential of damage or need to be worked on for repair. If the expert has the ‘trouble-shooting’ charts available at home and the technician at the plant floor is not able to search, he will quickly be able to guide using annotations, video references and pdf files.”

“We are also using AR for making SOPs, when machines are dismantled, we make our engineers stand there and wear the AR Glasses, they record the process and later on create AR based SOPs with that” we had never thought about that use case, but as we keep using AR, more and more use cases are emerging.

On VR AR being part of the same spectrum but having different use cases

The speakers were of the consensus that both AR & VR had their different set of use cases and the technologies should not be mentioned in an interchangeable manner.

Mr Sarnot shared “VR is for training & safety; while AR is for maintenance, inspection, services, SOP generation. I would like to add another dimension here, that of productivity improvement where AR can be used effectively as well. Lastly AR too can be used for safety”

Challenges & Gaps.

Mr. Swapnesh Pattnaik expressed that in an ideal situation, basic connectivity infrastructure must be built first and then higher technologies must be adopted. But waiting for infrastructure to fully fall into place will also make things late, so in reality it is about adopting technologies and building infrastructure to make it effective as a parallel effort. “ In our company we have a lot of capex allocations for infrastructure development and technology adoption” he stated, adding that two gaps that really need to be addressed are connectivity and training of people to be up to date with the latest technology”

Speaking next, Mr. Manchanda shed spotlight on the main challenge that companies face whilst they try to integrate Industry 4.0 technologies which is getting in synchronization with the OEMs, infrastructure and aligning the mindset of the people.

Speaking about a general mindset of India’s Business Sector, Mr. Sarnot said that “As Business leaders mostly we talk about ROI however the benefits that a technology might bring cannot be fully realized in advance”. He also acknowledged Mr. Pattnaik’s view on the importance of training and said “Another reason for a gap in the promise of technology and the delivery is that we don’t allow the training to be efficiently completed”. Mr. Sarnot further established his belief that efficient training can reduce the gap in the promise and delivery of technology by 5%.

Building on what Mr. Pattnaik said, Mr. Manchanda explained that for the industry to fully embrace technology, the people working in the industry should accept it with open arms. Addressing a cliché regarding increasing productivity, Mr. Manchanda beautifully said “Productivity doesn’t mean a loss of manpower. It means improving the efficiency of existing manpower”.

The panel on immersive technologies was truly an engaging and immersive one, thanks to its wonderful speakers having so many insightful perspectives to share.

What are your experiences and perspectives on Immersive technologies in Manufacturing and plant operations? Let us know…

Post by – Paranjey Patel, Business Team, VAMRR Technologies.

remote Productivity interests you?

May we request you to share your details and we will be glad to reach out to you with details of our remote productivity tools and solutions.